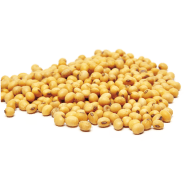

Green peas are harvested at their technological maturity when the sugar content is around 5% and the starch content is around 7%. At this stage, the peas are pleasantly flavored, soft, and juicy. As the peas mature further, the sugar converts into starch, resulting in a harder consistency and a starchy taste, which diminishes the quality of the flavor. The pods mature from the bottom upwards, so optimal yields with the best quality are achieved through multiple harvests. The yield of pods can range from 8 to 15 tons per hectare.

For peas intended for canning, the degree of maturity is very important. The majority of the sugar should not convert into starch, as this reduces the quality for canning.

The maturity stage of peas can be determined through chemical analyses, by measuring the content of starch and sugar, or more commonly, by determining the amount of alcohol-insoluble substances (ANS). In addition to these, there are also physical methods based on determining the specific mass of the seeds.

Mechanical Method

The most commonly used method is the mechanical method. It is based on measuring the resistance to crushing the seeds using a device called a tenderometer, which determines the degree of tenderness. The optimal value for harvesting is around 90 – 100 tenderometer degrees. For freezing, the optimal tenderness or technological maturity is between 90 – 120 tenderometer degrees. At this level of maturity, the seeds have a fine, delicate consistency with a much higher sugar content than when they are more mature.

Peas for canning are harvested using mechanized means. The combine harvester is a complex machine that performs operations such as cutting the crop, separating the pods, shelling, and cleaning the seeds. Its output is not large (around 20 hectares per day). Therefore, the harvesting schedule must be adjusted so that the combine harvesters can gather all the peas at the optimal maturity for harvesting. A delay of just 2 – 3 hours during hot weather can increase the tenderometer reading from 100 to 130. The loss during combine harvesting is 20 – 30%. The harvested seeds are collected in a bunker within the combine. From there, they are emptied into tractor trailers and transported directly to the factory for processing. The peas must be processed within 2 to 3 hours, as they have a high moisture content (85 – 90%) and a high protein content (5 – 6%). Additionally, the high temperatures during harvest time further accelerate undesirable changes, among which the most significant are the transformation of sugar into starch, increasing seed hardness, and spoilage caused by the development of microorganisms.

Harvested peas intended for sale must also be delivered to the point of sale as quickly as possible, as the ripening process continues after the pods are picked. The ripening process can be slowed at a temperature of 0°C and a relative air humidity of 95 – 98%. Under these conditions, they can be stored for up to 15 days.